Repairs,

Renovations, and upgrades 2022:

For the first few years after her trip Miss Cindy

was in outdoor storage on Vancouver Island.

Because her hatch drains got clogged with pine needles there was some

damage to hatches from fresh water accumulation there. From 2014 on she was stored under cover.

Repairs or renovations undertaken in 2022:

Replaced lower drop

boards in cabin hatch and repaired upper drop board.

Replaced starboard

cockpit hatch and repaired adjacent area.

Repaired

front edge of cabin top hatch.

Repaired

port cockpit hatch.

Repaired

port cockpit locker side wall with penetration of epoxy into drilled holes in

side wall.

Minor joint cracks

filled with epoxy and painted.

Couple of cosmetic

bubbles in glass repaired.

Resealed cabin windows

with Sikaflex

Bow net was removed and

washed. Bow net timbers and fastening were repaired as needed. Net reinstalled.

New additions in 2022 included:

Two braces were added

to the forward windows.

The solar panel arch

had reinforcing added to support the self steering

gear. Also spectra cross bracing added.

The mainsheet

attachment point were reinforced with fiberglass and longer screws used to

attach.

A brace was added to

the hulls mid cabin.

Wind vane self steering was added.

This is a horizontal axis, direct to tiller gear. Knots and a Knot

stopper on the tiller allow for engagement.

Main booms which were

felt to be a bit light were replaced with schedule aluminium

pipe about 250% stronger.

New furler

drums were built onto new main booms.

Front boom chain plates

replaced with 50% heavier material.

The original tiller and

attachment to the rudder shaft was problematic.

Tiller rebuilt and SS cheek plates used instead of Aluminium.

Rudder shaft reinforced

with solid rod welded in at head.

New 35AH AGM battery

installed.

New anchor light and

mount installed.

Temporary masthead

block padeyes installed in Cayman islands

replaced with bolt on investment cast pad eyes.

On her 2008 2009 cruise

I put on some temporary chafing gear.

The areas of chafe were where the battens and upper booms touch the mast

and where the lower boom and or reefed sail on the lower boom touch the mast.

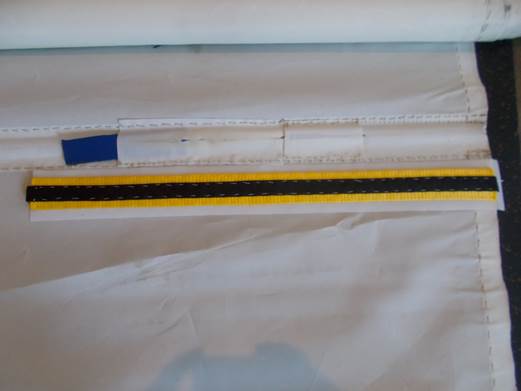

In 2022 I removed the

temporary chafing gear and sewed on 2” wide thick polyester webbing over those

areas. For good measure I added 1”

ballistic type nylon over that.

The bottom paint was

done in 2022 with a base coat of Black Interlux

Micron and a final cote of Red Interlux Micron. There is a final turtle motif painted in

Black Micron.

Repairs and renovations:

New additions:

Interior and spare vanes 2022

On trailer 2022

Things

that still need improving:

For chafe protection

when reefed a closed cell foam collar wrapped with rope should be added over

the masts where the boom contacts, probably about a 6 inch collar.

On sea trials I found a

small area in the port foredeck that was a bit soft. This can probably be repaired with

penetrating epoxy.

The self

steering would benefit from friction reduction,

here are some suggestions for improvements:

Casting a cylindrical

counterweight to replace the two cannonballs would allow for a counterweight of

perhaps 2 lbs vs the current 2.75 which would reduce

bearing friction.

The current vanes are

just test units made of 1/8 doorskin plywood. The short ones would probably be good for

strong winds but for light and medium winds lightweight vanes would help reduce

the minimum wind speed needed. The 6” x

48” on could be made with 1/32” birch ply skins and a light weight ¼” core or

honeycomb.

Use

3/32” spectra for the tiller control line.

Foredeck

inspection hatches leak and need to be rebedded.

Front

deck inspection hatches leak and need to be rebidded.

The

boards on the trailer deck need to be refastened. They tried to float off when launching and

recovering.